Description

Agricultural Combine Harvester Feeder Chain

A common combine harvester feeder chain comprises an inclined conveyor shaft and a drivable sprocket. The sprockets are welded onto the upper inclined conveyor shaft and are fastened in a variety of ways. In some cases, a straw walker 32 is used in place of the multidrum threshing assembly. The multidrum threshing assembly can also include a deflector roller.

| Chain No. | Pitch | Roller diameter | Width between inner plates | Pin diameter | Pin length | Inner plate depth | Plate thickness | Transverse pitch | Ultimate tensile strength | Average tensile strength | Weight per meter | |

| P | d1 max | b1 min | d2 max | L max |

Lc max | h2 max | T max |

Pt | Q min |

Q0 | q | |

| mm | mm | mm | mm | mm | mm | mm | mm | mm | kN/lbf | kN | kg/m | |

| 08B-1 | 12.700 | 8.51 | 7.75 | 4.45 | 16.7 | 18.2 | 11.80 | 1.60 | – | 18.0/4091 | 19.4 | 0.69 |

| 08B-3 | 12.700 | 8.51 | 7.75 | 4.45 | 45.1 | 46.1 | 11.80 | 1.60 | 13.92 | 47.5/10795 | 57.8 | 2.03 |

| 10A-1 | 15.875 | 10.16 | 9.40 | 5.08 | 20.7 | 22.2 | 15.09 | 2.03 | – | 22.2/5045 | 29.4 | 1.02 |

| 10A-2 | 15.875 | 10.16 | 9.40 | 5.08 | 38.9 | 40.4 | 15.09 | 2.03 | 18.11 | 44.4/10091 | 58.1 | 2.00 |

| 12A-1 | 19.050 | 11.91 | 12.57 | 5.94 | 25.9 | 27.7 | 18.00 | 2.42 | – | 31.8/7227 | 41.5 | 1.50 |

| 16A-1 | 25.400 | 15.88 | 15.75 | 7.92 | 32.7 | 35.0 | 24.00 | 3.25 | – | 56.7/12886 | 69.4 | 2.60 |

| 80H-1 | 25.400 | 15.88 | 15.75 | 7.92 | 36.2 | 37.7 | 24.00 | 4.00 | – | 56.7/12886 | 71.4 | 3.10 |

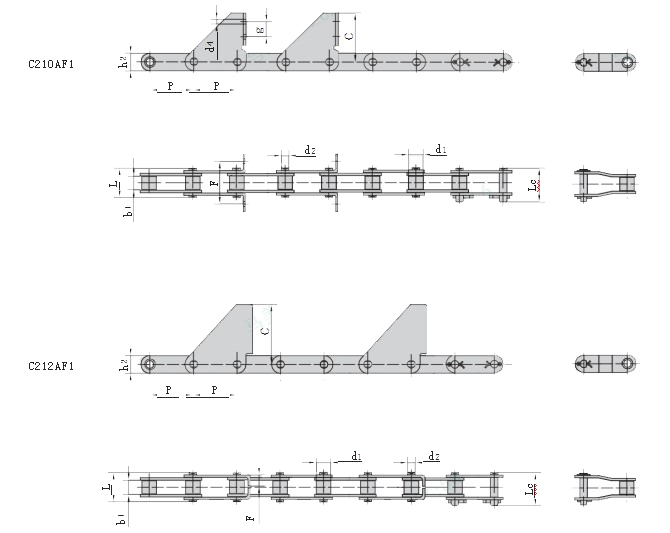

Agricultural Combine Harvester Chain C210AF1 C212AF1 Combine Chains

The chain is made up of several components. The first bearing arrangement is axially movable. The other elements are fixed to the sprocket. The sprocket and belt pulley is connected to the combine harvester’s drive train. In a similar way, the belt and chain are connected via the tractor’s drive train. A combine harvester can be equipped with different types of feeder chains.

| Chain No. | Pitch | Roller diameter | Width between inner plates | Pin diameter | Pin length | Inner plate depth | Attachment dimension | Ultimate tensile strength | Average tensile strength | ||||

| P | d1 max | b1 min | d2 max | L max |

Lc max | h2 max | F | C | d4 | g | Q min |

Q0 | |

| mm | mm | mm | mm | mm | mm | mm | mm | mm | mm | mm | kN/lbf | kN | |

| C210AF1 | 31.75 | 10.16 | 9.40 | 5.08 | 20.7 | 23.3 | 15.0 | 35.20 | 54.0 | 7.0 | 23.0 | 21.8/4955 | 28.5 |

| C212AF1 | 38.10 | 11.91 | 12.57 | 5.94 | 25.9 | 28.3 | 18.0 | 10.92 | 56.0 | – | – | 31.1/7068 | 38.7 |

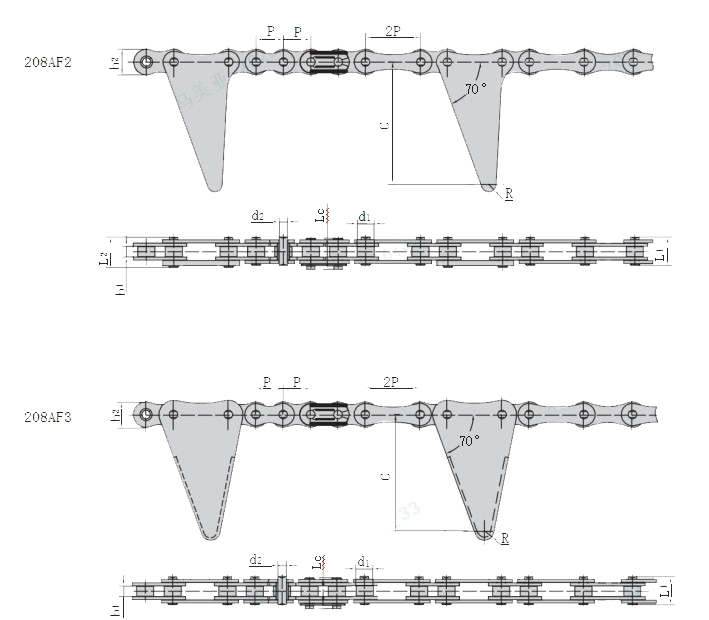

208AF2 208AF3 208AF3A 12.7 Pitch Combine Chains

These combine chains are made of high quality alloy steel production. The plates are punched and squeezed bores by precision technology. The pin, bush, roller are machined by high-efficiency automatic equipment and automatic grinding equipment, then through heat treatment of carburization, carbon and nitrogen protection mesh belt furnace, surface blasting process etc. Made from the steel and the up-to-date skills as well as precision procedures, the combine chains can withstand strong pressure and high temperature.

|

Chain No

|

Pitch

|

Roller diameter

|

Width between inner plates

|

Pin diameter

|

Pin length

|

Inner plate depth

|

Attachment dimension

|

Ultimate tensile strength

|

Average tensile strength

|

|

P

|

d1 max

|

b1 min

|

d2 max

|

L1

/L2 /Lc max

|

h2 max

|

C/R

|

Q

min |

Q0

|

|

|

208AF2

|

12.7

|

7.95

|

4.80

|

3.96

|

13.1/14.7/14.5

|

12.0

|

56.5/3.5

|

13.8/3136

|

16.0

|

|

208AF3

|

12.7

|

7.95

|

4.80

|

3.96

|

13.1/-/14.5

|

12.0

|

60.5/4.5

|

13.8/3136

|

16.0

|

|

208AF3A

|

12.7

|

7.95

|

7.85

|

3.96

|

16.6/-/17.8

|

12.0

|

60.5/4.5

|

13.8/3136

|

16.0

|

ZGS38 Combine Chain with Attachments

|

Chain No. |

Pitch | Roller diameter | Width between inner plates | Pin diameter | Pin length | Inner plate depth | Plate thickness | Ultimate tensile strength | Average tensile strength | Weight per meter | |

| P | d1 max | b1 min | d2 max | L max |

Lc max | h2 max |

T max |

Q min |

Q0 | q | |

| mm | mm | mm | mm | mm | mm | mm | mm | kN/lbf | kN | kg/m | |

| ZGS38 | 38.0 | 16.0 | 22.00 | 9.0 | 39.0 | 43.0 | 21.5 | 3.0 | 40.0/9091 | 55.3 | 2.00 |

| Chain No. | P | G | F | W | h4 | d4 |

| mm | mm | mm | mm | mm | mm | |

| ZGS38F2 | 38.0 | 16.0 | 52.0 | 71.5 | 19.6 | 11.0 |

| ZGS38F6K1 | 38.0 | 16.0 | 52.0 | 74.6 | 19.6 | 8.5 |

| ZGS38F10K1 | 38.0 | 20.0 | 52.0 | 72.0 | 17.0 | 8.4 |

| ZGS38F13K1F1 | 38.0 | 20.0 | 52.0 | 80.0 | 17.0 | 8.6 |

| ZGS38HF12K1F1 | 38.0 | 25.0 | 52.0 | 72.0 | 17.0 | 8.4 |

A correctly adjusted combine harvester feeder chain is essential to a productive and efficient harvest. If not adjusted correctly, the corn head cross auger may be clogged with too much material. This can lead to excessive material at the feeder house, causing a huge headache. For best results, adjust the chain as close as possible to the corn head cross auger. Ensure proper chain operation to avoid the ears piling up and damage.