Solution Description

Fisheries Forestry LuGong Transmission Components for Agricultural Rotavator Rotary Tiller

one. The body is created of thickened steel plate, which is robust and resilient, successfully reducing the vibration generated by the motor and prolonging the life of the device

2. The engine adopts a four-cylinder 490 Changchai engine, which is full of electricity and minimal fuel intake

three. The specific gearbox for crawler is shaped in 1 piece, and the rear energy output and the walking box are in the very same gearbox, so that the going for walks and the rear electricity output are far more coordinated.

tune. The unilateral electricity minimize-off steering can change 360° on the place, creating the turning and steering far more flexible. There are dual brake techniques to make the braking impact

Greater fruit. There are 4 ahead gears and 1 reverse equipment, respectively with higher and low gears, a complete of ten gears. Rear energy output details are large and reduced

Gear, 720 rpm at large pace and 540 rpm at lower pace.

four. There are powerful pressure cylinders at the entrance and back again, which can recognize robust lifting and robust falling, and the operation is much more secure

five. The special crawler for paddy fields is adopted, which has a big adhesion region, robust gripping capability, no slippage, no idling, and enhances operate efficiency. The crawler is thickened and widened to 35

cm, the total equipment weighs only 1.5 tons. The light-weight human body, high chassis and vast crawler can truly understand the twin use of water and drought, and the vehicle will not get trapped in the mud.

6. The chassis reinforcement value is as higher as 37 cm to enhance the passing efficiency of the equipment

seven. The one aspect adopts the style of setting up 1 driving wheel, 6 supporting wheels, 2 top wheels, and 1 tensioning wheel, and employing 6 supporting wheels can successfully

The fat of the equipment is dispersed to each wheel, thus reducing the bodyweight of the wheel and generating the wheel a lot more durable and wear-resistant

8. The turning of the equipment adopts unilateral hydraulic cut-off electrical power, which lowers the wear on the brake (disc and pad) and prolongs the services daily life

nine. The sheet metal areas of the device are made of thickened metal plates previously mentioned T4, which are powerful and resilient, not easy to deform, and the paint coloration is produced of higher-high quality spray powder, which has great adhesion

Big and temperature resistant.

10. The rear-mounted suspension (with suspension) is suitable with all wheeled tractors and agricultural machinery

eleven. The hydraulic program of this car is hydraulic transmission oil, which is resistant to higher temperature and is outfitted with an 80-mesh filter, which can efficiently filter iron filings and impurities in the transmission oil. Refill fluid

The strain oil radiator minimizes the temperature of the transmission oil in the course of use to steer clear of damage to the gearbox and control failure

12. Set up a h2o tank radiator to enhance the water tank potential, which can efficiently decrease the large temperature produced by the engine in the course of use

thirteen. The air filter is a dry filter, which can filter a large amount of dust and mud. After each and every function, clean the air filter and blow the dust inside

14. The diesel tank has a large ability and a long battery lifestyle

fifteen. It is suited for small and medium-sized paddy fields, swamps, muddy fields, biased fields and other harsh environments. It is specifically suitable for modest and medium-sized farmers and growers.Launch the labor force and greatly increase the operation efficiency

1. With a fifty-horsepower engine, a fifty-horsepower Changchai engine is optional. The patented solution of variable speed gearbox, reliable overall performance, there are 4 forward gears

1 equipment with high and reduced speed, 1 reverse gear with high and lower speed, a complete of 8 forward gears, with neutral and reverse. The rear output of the gearbox has 2 gears

Velocity, low pace 540 rpm, substantial pace 720 rpm.

two. The steering of the machine adopts hydraulic forced unilateral brake steering, and the steering process has its possess minimize-off energy, which can successfully shield the gearbox and braking program and make it

Much more resilient. The machine has rear output, suspension and sturdy raise, and can be matched with wheeled tractor implements. An optional bulldozer blade can be put in in front of the fuselage.

As properly as the loader bucket, it actually realizes a multi-function device, and the agricultural engineering is proper.

3. The design of the belt tractor has much better adaptability than the wheeled kind, the chassis is reduced, the stability is great, and the crawler adhesion coefficient is massive, which can effectively resist tilting and

Downhill slope. The crawler rotary tiller is an all-terrain operation device, which has the mobility of turning and steering in place, and has more powerful climbing and off-highway performance.

ZheJiang LuGong Machinery Co., Ltd was started in March 2000 which found at the junction of 3 cities(HangZhou, HangZhou and HangZhou)-HangZhou HangZhou industrial trade park and it truly is the spine organization of construction machinery national broad with mounted asset 500million Yuan. It handles a land of two hundred thousand square meters and has 1,one hundred staff, 88 of whom are engineers and technicians.

Our company mostly generates loaders, excavators, tippers, tricycles and so forth. Products are mostly bought to above twenty provinces in China and exported to dozens of nations and areas in Africa, Southeast Asia, South America and Russia. The quality and efficiency of our little farm-use loaders and design tippers are in leading place of the business throughout the country and nicely acquired by customers. Now, “Lu Gong” brand name loaders and tipper have received acceptance by sellers and utilizes all over China.

We focus on quality, efficiency and consider of customers as often. In management, we’ve achieved a new amount by adopting ISO9001:2015 global top quality management method.

We would like to create in financial design by holding our outdated and new friends and end users hands by pursuing our organization philosophy of “Pushed by science and engineering, in search of survival by good quality, benefiting by handling and winning market by provider” and spirit of “Pioneering, innovating and pursuing excellence”.

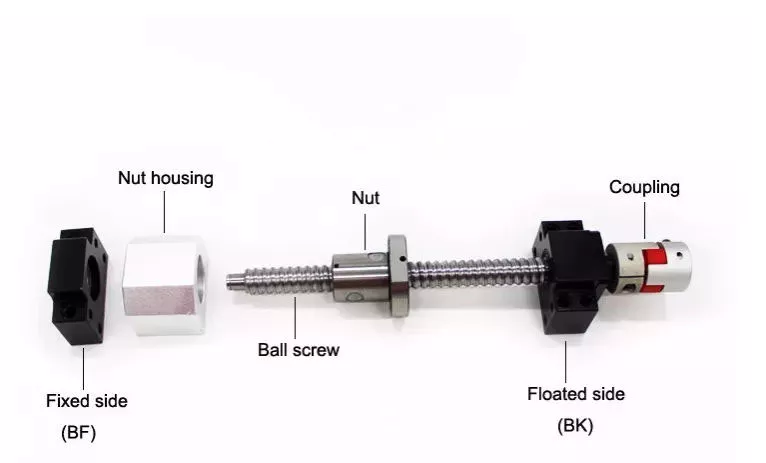

Advantages of Ball Screws and How They Can Benefit Your Applications

When selecting a ball screw for your application, there are several factors to consider. This article will discuss high mechanical efficiency, low friction, multiple repair options, and application requirements. Choosing the right ball screw can help you get the job done quickly and effectively. To make your decision easier, consider the following tips. Read on to learn about some of the advantages of ball screws and how they can benefit your applications. Here are some of the most common types:

High mechanical efficiency

The mechanical efficiency of ball screws can be measured using the axial load test. The axial load is equal to 0.5 x FPr / 2Fpr. The elastic deformations are measured as DL1 and DL2, respectively. Common engineering procedures work at 90 percent reliability; however, certain sectors require higher reliability, which has a direct impact on the dynamic load capacity. The axial load test is one of the most widely used methods to determine the mechanical efficiency of ball screws.

In order to achieve high translation, ball screws must be designed with high stiffness and positioning accuracy. In addition, high preloads increase the initial driving torque and cause more friction and heat. Other important design criteria include low driving torque and reduced slip motion. This means that the high translation capacity of ball screws must be well matched to the overall application. The following are some common design criteria for ball screws. You can select the best type of ball screw for your needs.

The high mechanical efficiency of ball screw is achieved by avoiding the common sag and pitch problem. The ball track design helps to reduce the centrifugal force. The ball screw’s diameter can be adjusted by adjusting the centre pitch of the nut on two ball tracks. The nut’s axial load is also adjusted through the offset centre pitch. This method allows the users to increase the mechanical efficiency of ball screw by up to 40%.

When calculating the mechanical efficiency of ball screw, consider the application’s environment, speed, and other factors. If the application requires precision and accuracy, then the ball screw is the right choice. The engineering department of a ball screw manufacturer will carefully review the application factors and come up with a design that meets the application’s expectations. Moreover, some manufacturers even offer customized ball screws, which can be tailored to your requirements.

Low friction

The operating performance of a low-friction ball screw is characterized by its minimal friction. This screw has a structure that transmits forces through rolling steel balls. The torque is calculated by calculating the load and the lead screw’s dimensions. This type of screw can be used for a variety of different applications, including hydraulic systems. Read on to learn more about this type of screw and how it can help you build a more reliable and durable car.

The critical speed of a ball screw is higher than that of a lead screw, so this type of screw can accommodate larger loads and speeds. It also has a lower friction coefficient, which reduces the amount of heat produced. High-quality ball screws can withstand longer duty cycles than standard lead screws. However, in order to compare the two, you must take into account the duty cycle. Low-friction ball screws are more durable than lead screws, and the duty cycle is only one of the factors you should consider when selecting them.

The ball bearings are the most prominent component of a low-friction ball screw. Their main function is to reduce the friction between the nut and the shaft. Without them, the friction would be too high. This feature is possible thanks to the ball bearing’s groove profile. Two arcs intersect at the contact points on the shaft and nut. Consequently, the ball bearing reduces friction in a way that is essentially non-existent without the bearing.

The mechanical efficiency of a low-friction ball screw is very high. The typical ball screw is up to 90% efficient, but some types can reach a higher efficiency. They are commonly used in machine slides, presses, and linear actuators. The high efficiency of a low-friction ball screw makes it a great choice for many different applications. This type of screw is made of several main components. The ball bearings provide the helical raceway for the ball assembly and threaded shaft is the screw part. The ball screw is comparatively more bulky than a conventional leadscrew, but the overall size is smaller than its lead counterpart.

Multiple repair options

A damaged ball screw will typically display visible physical signs, including noise or vibration. Additionally, worn ball screws will require more horsepower and torque to operate. They may also cause lead accuracy issues. Luckily, there are multiple repair options for ball screws. You can get new ball screws to restore preload and reduce backlash. But there are some warning signs to look out for first. Keeping a close eye on your ball screw’s health can help you avoid a costly replacement.

Look for a ball screw repair company with a proven track record of servicing all types of ball screws. The service should offer a free evaluation and three types of service: reload, recondition, and replacement. Reload is the simplest option and involves cleaning and polishing the screw and ball nut. Reconditioning or replacement, on the other hand, requires new parts. Choose the one that offers the best value for your money.

EP offers an emergency service and superior service for your ball screws. Their UK service includes delivery and international shipping. All ballscrew repairs are covered by a full service warranty, and the company is known for providing competitive pricing. If you do need a ball screw repair, look no further. Contact K+S today to discuss your specific needs. You’ll be glad you did. You’ll save up to 70% over purchasing a new ball screw.

While ball screw repair is an easy and inexpensive option, it may be necessary to have it replaced more frequently than the usual. In addition to replacing worn ball screws, you may need to consider a different type of repair. This process involves grinding the ball nut and journal diameters back to their original size. Fortunately, level 4 is the most expensive but can restore a screw’s lifespan. This is also the most extensive type of repair available for a ball screw.

Application requirements

A ball screw is an efficient solution for precision motion control in many applications, including automotive and aerospace. These screw-type devices are highly resistant to corrosion, and the alternating steel-ceramic architecture ensures extreme reliability and sturdiness. For the aerospace sector, a ball screw replaces the typical hydraulic system, and the product is used in wind turbine blade pitch and directional position, solar panel movement, and gate control in hydroelectric stations. Ball screws are also used in motorised inspection tables, step photolithography machines, microscopic integrated circuits, and many other applications.

The most critical requirements for a ball screw assembly are backlash and bearing support. Backlash is the amount of axial motion between the screw and nut, which leads to positioning errors. Although this axial motion is minimal, it can be as little as 70um. If the preload is too large, a ball screw may suffer from excessive heat. Depending on the application, the amount of preload required can be adjusted to maximize the overall performance of the device.

The choice of screw is determined by the load capacity. For example, plastic nuts are commonly used for light loads, while bronze nuts are used for loads that weigh several thousand pounds. Lead screws are not particularly reliable in situations where load requirements are extremely high, and a ball screw will often be a better option. The lower friction of a ball screw allows it to withstand higher duty cycles than a lead screw. When the load requirements exceed lead screws’ capacity, a ball screw is the better choice.

A step photolithography machine is another example of an application where ball screws play an important role. This device helps manufacturers produce microscopic integrated circuits by harnessing the reaction of light. A stepper is a critical piece of this machine, as it controls the positioning of light exposure on the silicon wafer. High precision is required for this application. Ultimately, a ball screw will make the process easier. Its proven record for meeting instrumentation requirements is an excellent example of its value in the laboratory.

Cost

The global market for ball screws is growing at a steady pace, but what drives the growth? In the ball screw industry, performance, cost, and analytical predictability are the primary concerns of OEMs. This market study provides in-depth analysis of these market dynamics. You’ll learn how to best compete in the global market for ball screws. Here are some tips to help you get started:

Ensure you have a good grasp of the differences between lead and ball screws. The cost of lead screws depends on their efficiency, and some of them can achieve C5 level accuracy. However, ball screws are more durable and more repeatable. Besides, lead screws can’t achieve high precision because of their sliding motion, which gradually grinds away the accuracy. As a result, the cost of a ball screw is more than compensated by the improved performance of OEMs.

To get the best price for ball screw, look for a manufacturer with a strong technical force. Most of these manufacturers have sophisticated equipment and strict quality control systems. They draw inspiration from the requirements of the market and have continuously increased their technological content to stay ahead of the competition. If you’re in Pune, look for a manufacturer with this technology. It won’t be difficult to do business with such a supplier. The company will also provide you with contact information, including their office address and phone numbers.

When choosing between lead and ball screws, you need to understand how they work and why they’re more reliable. Ball screws are more durable than lead screws, which is one of the primary reasons for their popularity. Lead screws, on the other hand, are often used for vertical applications. Lead screws tend to be cheaper than ball screws, but they have more limitations. When used properly, however, they can increase the life and performance of machines. In general, they’re corrosion-resistant and offer great design flexibility.